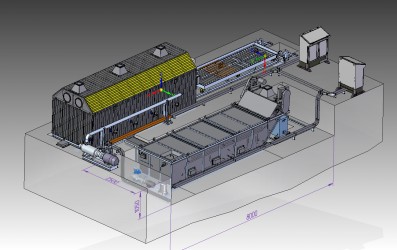

Washer for oil-field equipment (packers, valves)

Oil-field equipment washer is intended for cleaning packers, check valves, ball valves, throttles and other items sent for repair from oil products, paraffins and other impurities.

Washer construction allows to use it in many ways. Dimensions can vary depending on set task.

The washer shown on photo has the following dimensions:

- Maximum size of loaded item is 3500 х 2000 х 1600 mm;

- Maximum weight of loaded item - 1 000 kg.

Oil-field equipment washer comprises a washing chamber, solution preparation module, fixed rail cart, cart cable drive.

Washing chamber is covered inside with stainless steel sheets and outside - with corrugated sheets. Between them an insulant is placed. Pipes with nozzles are laid along walls, ceiling and floor inside the chamber. Chamber entrance is equipped with automatic door. Terminal switches (sensors) of cart movement are installed inside the chamber. The chamber is situated in a small cavity on the floor to prevent spreading of washing solution.

Water preparation module is a tank with heating elements or steam coil to heat washing solution. Also module is equipped with two drag conveyors to remove mud, low and high pressure pumps and drain pump. The mud is removed to receiving container that is afterwards lifted by crane to the surface and discharged.

Cart is a welded construction with wheels, moves by cable drive.

Set operation:

- Item (or items) is put on the cart, fixed if necessary. The cart is in initial position. The solution is heated. Water is not delivered no nozzles. Chamber door is open.

- Operator presses the button “Start”.

- Cable drive is activated. The cart moves to the chamber. The door closes. Solution starts delivering from the preparation module. The liquid is sprayed from nozzles to item. The cart with shuttling movement moves in chamber during determined cycle. Solution is drained back to module.

- When washing cycle is finished solution delivery stops. Dwell of the cart. Solution is drained. The door opens and cart rolls out.